|

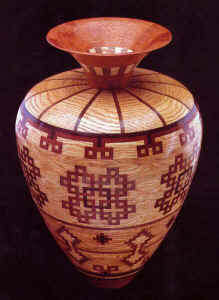

Celtic Mood

This page describes some of the details of the construction of this

vase. Unfortunately at the time of construction I did not take as many

photos as I would have liked to, so there are only a few detail shots.

'Celtic Mood' is a 13 1/2" diameter, 19" tall vase. There

are 2164 pieces of wood glued together to make up the vase. There are 4

types of wood - Padouk (red), Walnut (brown), African Blackwood (black),

and Oak (the background). Construction

of this vase took about a month, working almost every day.

|

|

I started with a detailed, full-sized drawing of the shape and

patterns. This design work was done over a period of a couple of months.

There were lots of ideas about patterns, colors etc. that took some time

to decide upon. I used a 1/4" grid paper and constructed the entire

vase (with the exception of the base and part of the top) from 1/4"

thick segments.

I did most of the cutting ahead of time. I used a simple jig on my

table saw to accurately set the width of the small pattern pieces. As

can be seen from the closeup photo of the celtic knot pattern, the

pattern is made up of pieces which are multiples of the 1/4" base

pattern width. These need to be cut very accurately in order to get the

visual effect of the knot to work. I did most of the cutting ahead of time. I used a simple jig on my

table saw to accurately set the width of the small pattern pieces. As

can be seen from the closeup photo of the celtic knot pattern, the

pattern is made up of pieces which are multiples of the 1/4" base

pattern width. These need to be cut very accurately in order to get the

visual effect of the knot to work.

The knot patterns were pre-constructed into horizontal assemblies of

2 or 3 rows. This assembly was constructed on the workbench, and clamped

tight to minimize glue lines. The top, bottom, and sides could then be

lightly sanded on a sanding disk to eliminate any slight

unevenness. This was by far the most tedious part of the process.

The pattern had to be followed exactly in order to get the final 'knot'

effect. (More than one 'mistake' is still kicking around my shop!)

This photo shows some of the construction pieces and partial

assemblies. I started all the walls with 1 1/2" wide pieces. This

was later turned down to a finished wall thickness of around 3/8".

|

| Once the major knot pattern assemblies were finished, I began

constructing and turning the vase. I constructed this vase in 4 separate

pieces. The individual pieces were glued and turned to about 5/8"

wall thickness. At this stage, the full-scale drawing is particularly

important. I could measure both the inner and outer diameter of each

ring. Before assembling the 4 main pieces, I turned the interior to it's

final finished size and sanded. The 4 pieces were then glued together. I

could then mount the entire vase between centers on the lathe and turn

the outside to it's final form and finish.

This

photo shows two of the four sub-assemblies. This

photo shows two of the four sub-assemblies.

The assembly with the 6 celtic knots was constructed and turned by

temporarily attaching it to a 14" diameter MDF disk which was

mounted on a faceplate. Note that the completed rings are a combination

of celtic knot pattern pieces which are cut at 90 degrees, and 'filler'

pieces of oak that are tapered. The entire celtic knot assembly is in

fact made up of 'square' pieces. This enables one to accurately align

the pattern vertically.

When most segmented-ring construction is done, the individual rings

are all glued together at once, then the entire ring glued to the row

below it. For this project I was most concerned about the vertical

alignment of pieces within the celtic knot pattern. I actually glued

each knot sub-assembly (the 2 or 3 row high pieces in the previous

photo) on separately, clamping it securely to the row below. This way I

could accurately align it with the piece below. Once the glue had set, I

fitted the tapered oak 'filler' pieces between the pattern assemblies.

(This often required some slight adjustment to the angle on the oak

pieces, which I did with a disk sander). |

The photo

to the left shows several of clamps used to hold on one of the layers

on the upper assembly. The top has about a 2" hole in it where the

final vase spout will be inserted. This hole was used during

construction to hold the piece with a scroll chuck so that it could be

turned and shaped. The photo

to the left shows several of clamps used to hold on one of the layers

on the upper assembly. The top has about a 2" hole in it where the

final vase spout will be inserted. This hole was used during

construction to hold the piece with a scroll chuck so that it could be

turned and shaped. |

This

final photo shows a closeup of the celtic knot pattern. There are

about 200 pieces of wood in each of these knots. The under-over knot

effect is critical to the overall result. It is also the part that

nearly drove me mad with frustration! More than once I came back to the

shop the next morning to find that I'd somehow messed up the pattern.

I'd then have to chip, cut, break, or turn off the offending pieces and

start again. The whole pattern was made more complicated by

interchanging the red padouk and the brown walnut on every second

knot. (I believe the appropriate term for this is 'glutton for

punishment'...) This

final photo shows a closeup of the celtic knot pattern. There are

about 200 pieces of wood in each of these knots. The under-over knot

effect is critical to the overall result. It is also the part that

nearly drove me mad with frustration! More than once I came back to the

shop the next morning to find that I'd somehow messed up the pattern.

I'd then have to chip, cut, break, or turn off the offending pieces and

start again. The whole pattern was made more complicated by

interchanging the red padouk and the brown walnut on every second

knot. (I believe the appropriate term for this is 'glutton for

punishment'...) |

|